Shasta - Replacing Bottle-to-Valve Amidite Line

Tools & Materials

The following tools and materials are required to complete this procedure:

- Screwdriver set (Phillips)

- ANSI Allen Keys

- Replacement liquid line tubing

- P-287 Idex Super flangeless fittings

- P-259 steel compression rings and ferrules

- Pliers

- Labeling materials (if transferring labels)

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Follow manufacturer guidelines for handling hazardous materials.

Procedure

- Remove all liquid from the liquid line

- Place an empty bottle on the troublesome position.

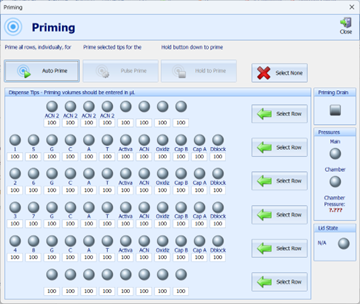

- Access the priming screen in the software and prime all liquid out of the line

- Depressurize the instrument

- Turn the ball valve for Amidite pressure to the off position

- Depressurize the instrument by removing the bottle from the troublesome location

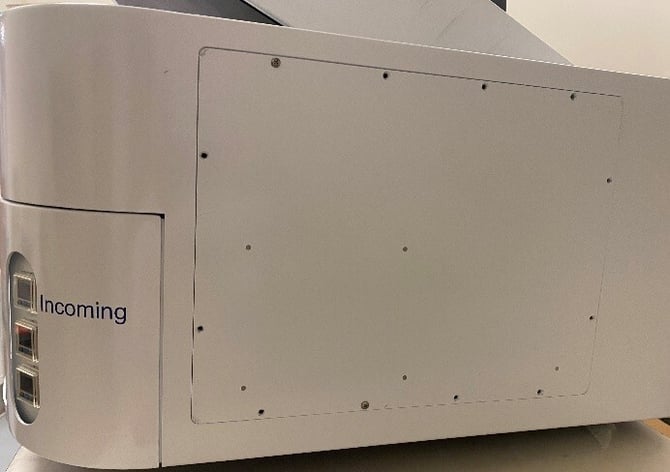

- Remove the Front Rack Sheet Metal

- Remove screws from the top of the front bottle rack sheet metal.

- Remove screws along the underside of the front bottle rack.

- Attempt to gently pull the sheet metal off.

Note: If stuck (especially on the right side), proceed to Step 4 to access hidden screws. Otherwise proceed to step 5

- Remove screws from the top of the front bottle rack sheet metal.

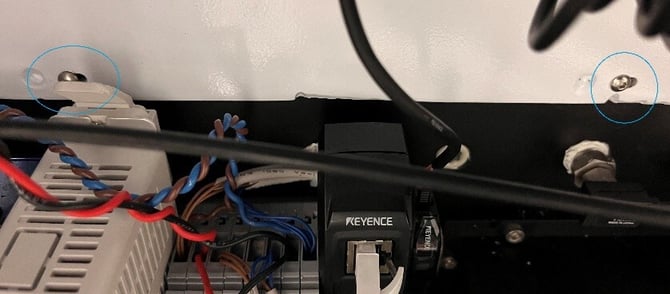

- Access Hidden Screws (if needed)

- Remove the side panel covering the electrical enclosure.

- Identify and remove up to 3 screws securing the interior sheet metal to the chamber.

- Remove screws along the top and underside of the back panel and side sections.

- Gently remove the side/back sheet metal panel to expose the remaining hidden screws.

- Remove the side panel covering the electrical enclosure.

- Remove Bottle Rack

- Remove the front cover completely.

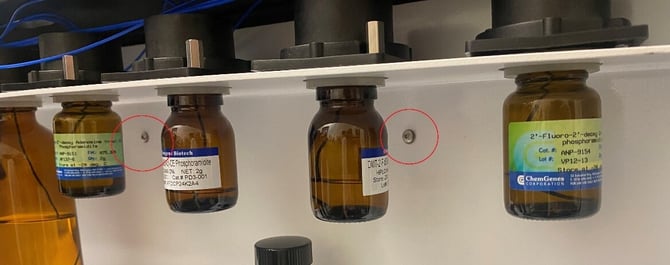

- Remove bottles to access mounting screws.

- Unscrew and gently pull the bottle rack away, setting it on a table for support.

- Remove the front cover completely.

- Identify and Remove Liquid Line

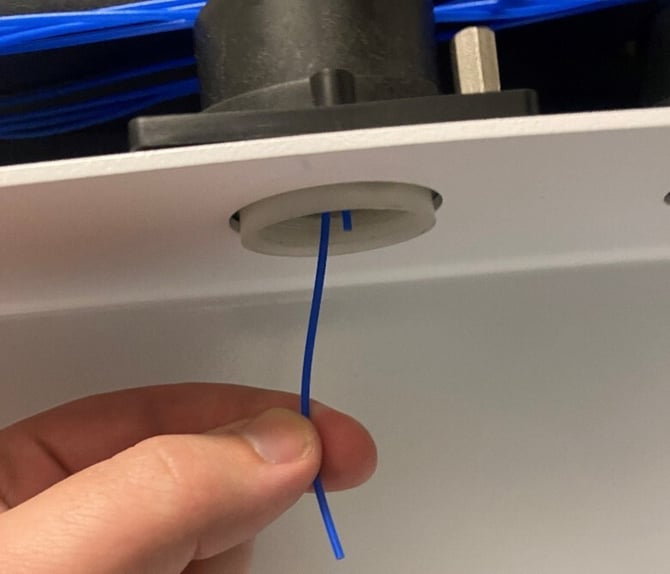

- Locate the liquid line for the position you are troubleshooting

- Pull the liquid line out from the top of the receptacle.

- Trace and Remove Liquid Line

- Open side panel covering fluid pathways.

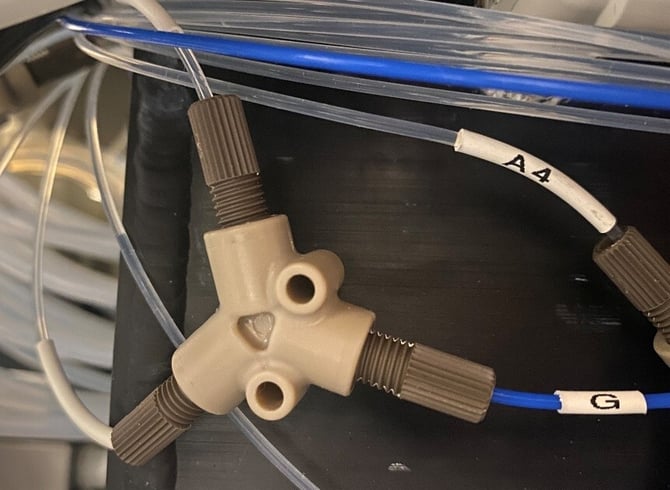

- Trace liquid line to Y connector.

- Remove all affected lines from Y fitting, dispense valves, and tips.

- Cut and prepare new tubing to match original lengths.

- Transfer any labels, if possible.

- Prepare New Tubing Ends

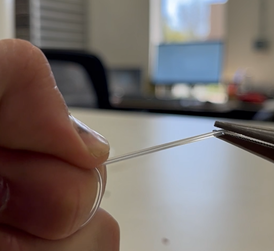

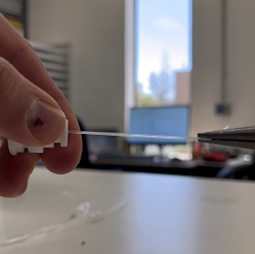

- Slide nut, compression ring, and ferrule onto tubing (in that order).

- Flattened side of ring should face nut; narrow side of ferrule toward ring.

- Use Y fitting or Peek union to seal ferrule/compression ring onto tubing.

- Slide nut, compression ring, and ferrule onto tubing (in that order).

- Reinsert Tubing into Bottle Cap

- Stretch the tubing end by looping around finger and pulling with pliers.

- Trim the flattened tip and feed stretched section through cap hole.

- Pull tubing through to bottle side using pliers.

- Ensure enough tubing reaches bottle bottom, trim excess length.

- Stretch the tubing end by looping around finger and pulling with pliers.

- Final Connections

- Connect all new lines to appropriate dispense tips, valves and Y fitting

- Reassembly

- Reassemble sheet metal panels in reverse order of disassembly

- Validation & Testing

- Turn on the equipment if it is not on already

- Place a bottle with liquid on the position corresponding to the line that was just replaced if not done already.

- Pressurize the amidite bottles again by turning the ball valve to the on position.

- Verify there are no leaks at any of the connection points for the line that was just replaced. (It might be helpful to leave side panels off)

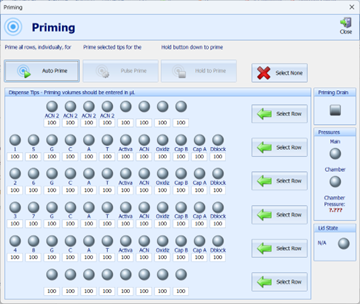

- Open the Software and access the Priming Menu

- Select the valve that corresponds to the amidite line that was just replaced

- Prime the valve and verify that the liquid is injecting into the waste tray

- Again verify no leaks at any connection points.