K&A - Monthly Compressor Maintenance Procedure

This procedure ensures proper function, efficiency, and longevity of the compressor by performing basic monthly maintenance: checking and refilling oil, draining water, and inspecting the air filter. Please refer to this VIDEO for further help.

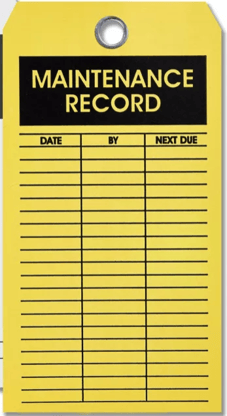

It is recommended that a Monthly Compressor Maintenance Log is kept and updated or a machine tag is kept on the compressor:

A template Monthly Compressor Maintenance Log can be downloaded here

🔧 Tools & Supplies

-

Lint-free wipes

-

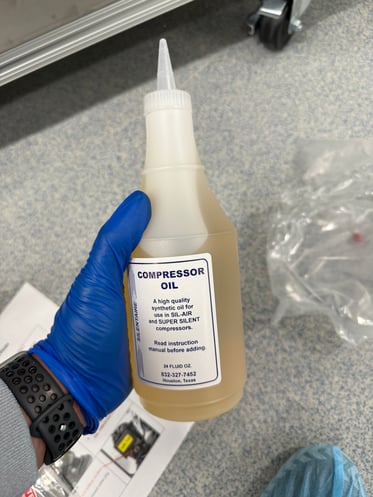

Oil (approved type from manufacturer)

-

Crescent wrench

-

Allen wrench (for filter assembly)

-

Flashlight (optional, for visual inspection)

-

Maintenance log

⚠️ Warnings

-

Always power off and depressurize the compressor before maintenance.

-

Orange or very dirty water may indicate a major internal issue—report this immediately.

-

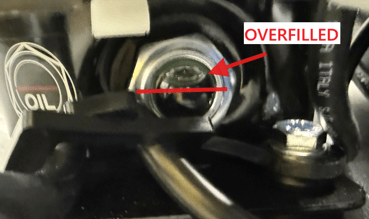

Do not overfill oil past the halfway point of the sight bubble.

✅ Step-by-Step Instructions

- Note the Compressor Pressure

- Note the current compressor pressure at both the instrument gauge and the compressor gauge itself to ensure there are no anomalies

- Typical ranges at instrument: 0.30 -.040MPa (43-58 psi)

- Typical ranges at the Compressor: 0.41 MPa-0.55MPa (60-80 psi)

Note: The compressor must always supply more pressure than the instrument is demanding otherwise it will behave as if it has a leak in the compressor air system.

- Note the current compressor pressure at both the instrument gauge and the compressor gauge itself to ensure there are no anomalies

-

Run SHUT DOWN Sequence

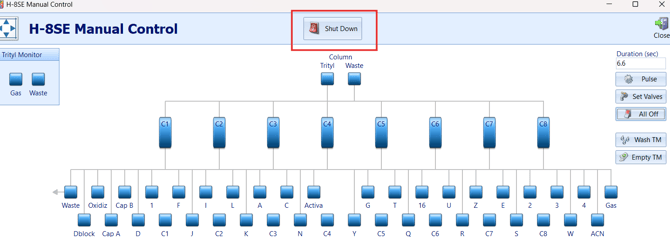

- In the software go to the Manual Control Screen

-

Follow all on-screen prompts until the liquids are in their respective bottles.

-

Double check to make sure no fluid remains in the liquid lines or waste lines.

-

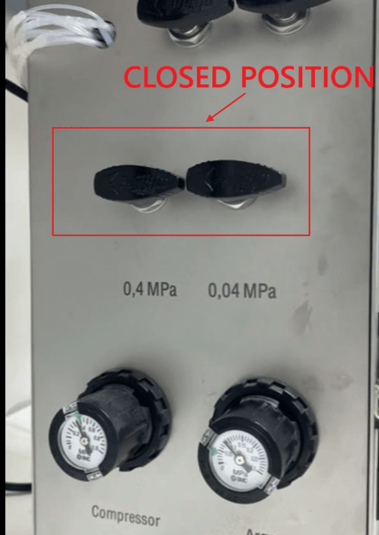

Once the lines are dry, close the Argon and Compressor Pressure turn Valves.

WARNING: FAILURE TO DO THIS CORRECTLY COULD LEAD TO CROSS CONTAMINATION OF REAGENTS. NEVER TURN OFF COMPRESSOR PRESSURE UNTIL ALL BOTTLES HAVE BEEN DEPRESSURIZED

- In the software go to the Manual Control Screen

-

Power Down and Vent System

-

Turn off the compressor using the main switch.

-

If needed, open the manual ventilation valve to release trapped pressure.

-

-

Check Oil Level

-

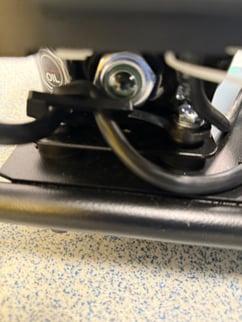

Locate the oil sight bubble (usually on the compressor’s right side in North American builds).

-

The oil should be at the halfway mark of the bubble.

-

If low, continue to the next step

-

-

Add Oil (If Necessary)

-

Use the compressor oil that came with the Compressor if available but standard air compressor oil from a hardware store will suffice.

-

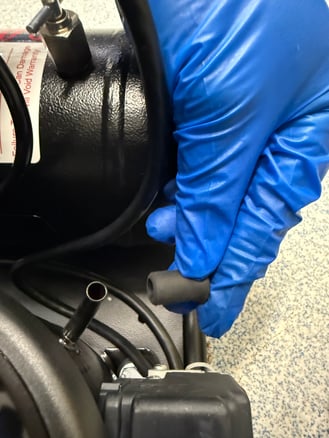

Remove the oil cap and slowly add oil using a clean funnel or tubing.

-

Watch the bubble closely—stop filling once halfway full.

-

Close the oil cap and secure it.

-

-

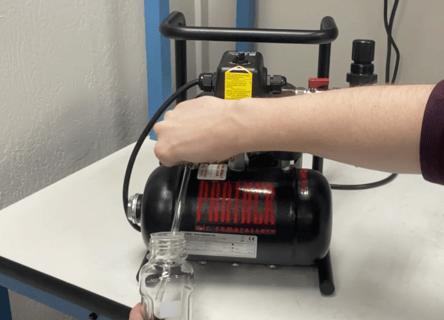

Drain Water Trap

-

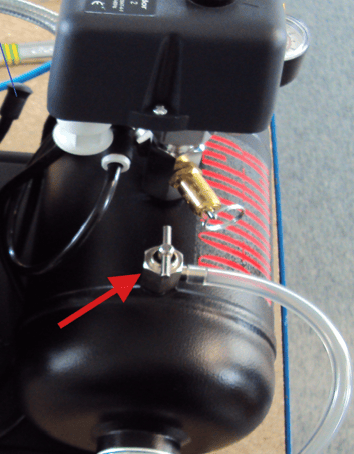

Locate the water trap release valve

-

Place a container to collect any water or residue under the tube connected to the valve

-

Open the drain valve to release any water or residue into the collection vial

- Close the valve once fully drained.

-

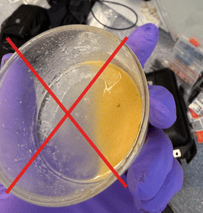

Inspect the drained water:

-

Clear or slightly cloudy – Normal

-

Orange, rusty, or sludgy – Flag this in the log and notify service immediately because if it is excessive you will likely need a new compressor.

-

-

-

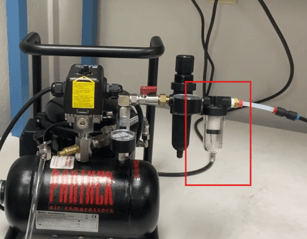

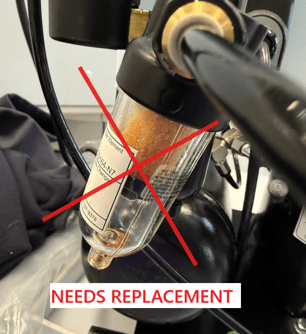

Inspect Filter and Tubing

-

Visually check the air filter for dirt or damage. The filter should be either white or green. Replace if you see discoloration.

-

Inspect compressor tubing for clogs, damage, or improper positioning.

Consider replacing the tubing if the compressor filter was very discolored as particulates or oil may have gotten into the tubing

-

-

Record & Report

-

Log oil level, water condition, and filter status in the monthly maintenance log.

-

Note any issues or anomalies and alert Sierra BioSystems

-