K&A - Maintenance Schedule

This guide outlines recommended maintenance tasks and their ideal frequency.

🗓️ Weekly Maintenance

Check Reagent & Amidite Levels

-

Verify that all bottles are filled to appropriate levels

-

Refill or replace any reagents nearing depletion

Visual Inspection

-

Inspect the instrument for leaks, salt buildup, or chemical residue

-

Confirm that no hoses or fittings appear loose or damaged

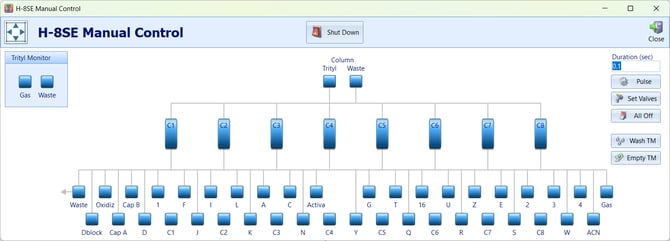

Run Shut Down Procedure

-

If the instrument will not be used for some time. perform a complete flush of the fluid lines using the Shutdown Procedure in the Manual Control Screen.

🗓️ Monthly Maintenance

O-Ring and Seal Inspection

-

Inspect seals on amidite and reagent bottle caps

Check Pressure Stability

- Refer to THIS VIDEO

-

Pressurize the system and monitor for pressure drop

-

A drop of more than 0.5 psi in 1 minute may indicate a leak

Valve Function Test

-

Use manual valve control to ensure each valve actuates with a clear click

-

Check for steady flow and even delivery from each valve

Flow Test

-

Perform a calibration check using a precision balance and graduated vial. Refer to THIS PAGE.

-

Dispense and measure output for each valve

-

Address any inconsistencies.

- If a Valve Replacement is necessary refer to THIS VIDEO.

Remove water and check oil level of Compressor

- Refer to THIS PAGE

-

Turn off the compressor

- Hold a collection vial underneath the line for the purge valve

- Open the Manual Water Remove Switch to remove all water

- Close the switch

- Turn the compressor back on

🗓️ 6 Month Maintenance

Inspect Manifolds and Internal Connections

-

Open the instrument and inspect reagent manifolds and pneumatic fittings

-

Look for signs of wear, leaks, or corrosion.

Replace Wear Components

-

Replace any valves with inconsistent performance. Refer to THIS VIDEO.

- Replace Main Delivery Manifold Membrane. Refer to THIS PAGE.

Software Backup

-

Backup configuration files and job data

🗓️ Annual Maintenance

Replace Wear Components

-

Replace O-rings, seals, and any tubing showing signs of fatigue

-

Replace any valves or regulators with inconsistent performance. Refer to THIS VIDEO.

- Replace ALL Membranes (Liquid Delivery Manifold and Waste Manifolds). Refer to THIS PAGE.

Deep System Clean

-

Flush all fluidic paths thoroughly

-

Clean interior and exterior surfaces using appropriate solvents

🧪 Additional Tips

-

Use only anhydrous acetonitrile or other compatible solvents

-

Always wear appropriate PPE during maintenance procedures

-

Log all maintenance actions in the system service log