K&A - How To Change a Membrane

Changing the membrane in the valve block is a routine but critical maintenance task.

This guide walks you through the full procedure to safely remove, clean, and replace the membrane on your 24-port K&A synthesizer main block.

There is also a video for this procedure here: K&A - Membrane Replacement

🔧 Tools and Supplies Needed

- 3 mm Allen Wrench

-

2.5 mm Allen wrench or Cordless power drill with 2.5 mm bit

Power drill runs the risk of overtightening the screw. Allen Wrench is recommended in most instances

-

8 mm wrench

-

Guitar string or similar flexible wire

-

Lint-free wipes

-

ACN (acetonitrile) or ethanol

-

Replacement membrane

-

Spare caps for sealing chemical bottles when instrument is unpressurized

-

Replacement M3 screws and flangeless fittings (if needed)

-

Access to PC with K&A control software

⚠️ Warnings

-

Always fully shut down and depressurize the instrument before disassembly.

-

Use caution with chemicals—seal bottles if left open.

-

Do not overtighten screws or fittings.

-

Use the correct torque setting on the drill to avoid damaging screw threads.

1. Shut Down and Prepare

-

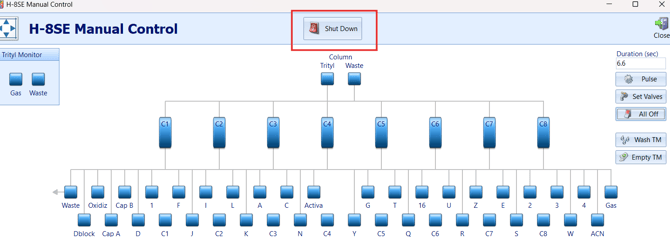

In the Software, open the Manual Control Screen and click SHUT DOWN.

-

Follow all on-screen prompts until all the liquid is in their respective bottles.

-

Double check to make sure no fluid remains in the liquid or waste lines.

-

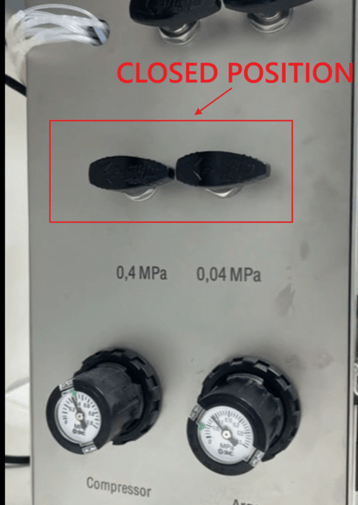

Once the lines are dry, close the Argon and Compressor Pressure Turn Valves

WARNING: FAILURE TO DO THIS CORRECTLY COULD LEAD TO CROSS CONTAMINATION OF REAGENTS. NEVER TURN OFF COMPRESSOR PRESSURE UNTIL ALL BOTTLES HAVE BEEN DEPRESSURIZED

2. Secure Chemicals

-

Remove all reagent and amidite bottle caps and seal the bottles with spare caps to prevent chemical degradation.

3. Disassemble the Manifold Block

-

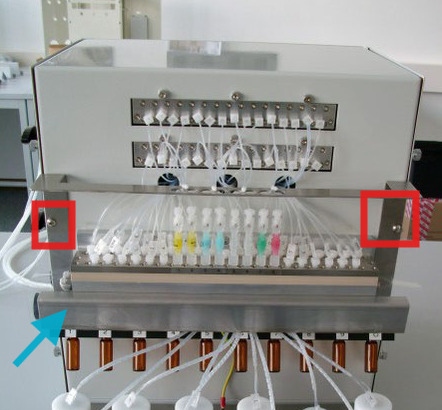

Remove the sheet metal loom above the column area using the 3.0 mm Allen Wrench

-

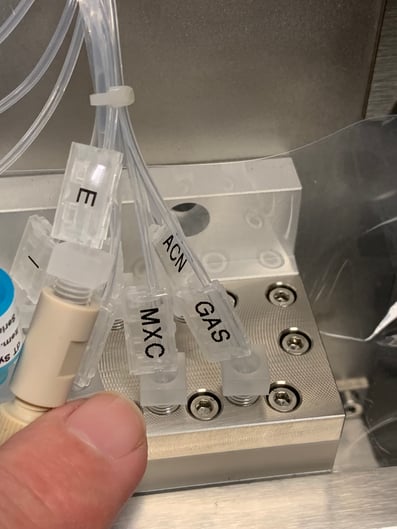

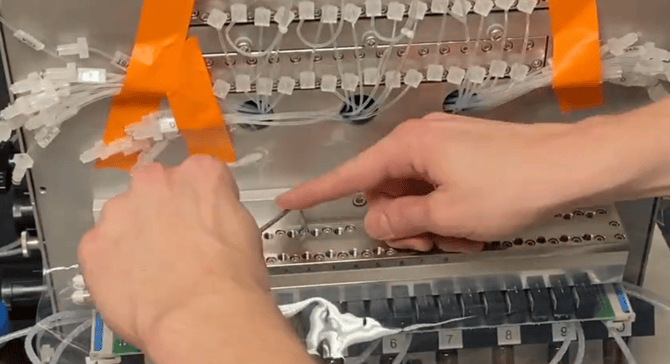

Loosen the fittings on the main block, and fully remove the column inserts. Tape can be used to hold the lines in place after detaching.

Hint: Take pictures and ensure the lines are fully labeled so that you return the fittings to the correct spot

-

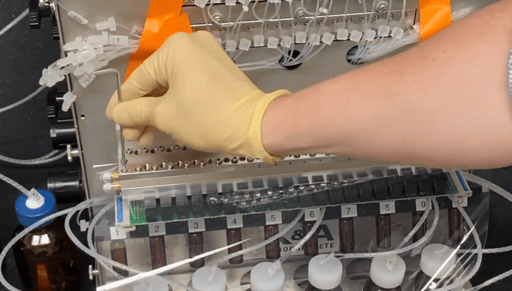

Use a 2.5 mm Allen wrench to begin loosening the manifold screws. A cordless drill (2.5 mm bit, torque = 0) can also be used to fully remove all screws.

WARNING: It is very easy to strip the screws so use allen wrenches or bits that are not worn

-

Inspect all screws—replace any with damaged heads.

4. Clean Components

-

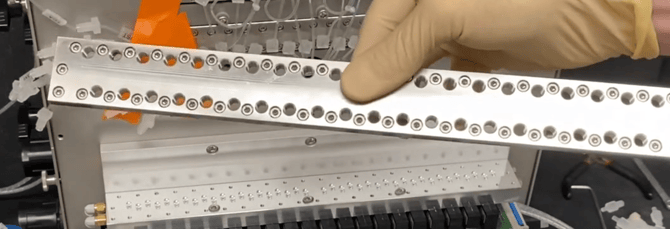

Remove the PEEK channel block and clean with ACN and a lint-free wipe.

-

Clear all ports on the PEEK channel using a guitar string to remove debris or blockages.

5. Replace Membrane

-

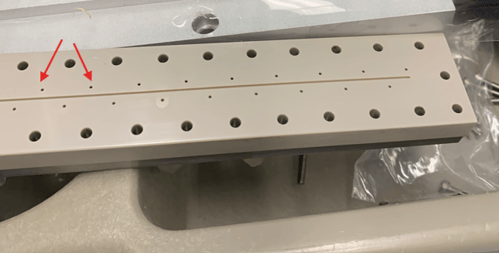

Remove the old membrane and align the new one so screw holes match the block pattern.

-

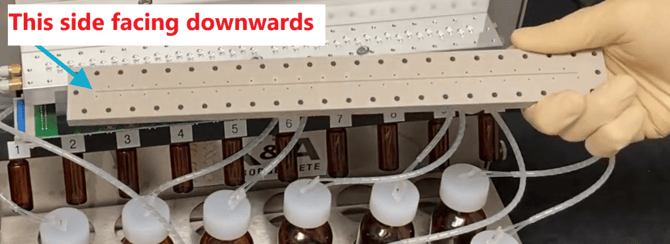

Place the membrane beneath the PEEK channel block and the valve block—make sure the channels on the Peek Manifold face downwards. The channels should face the membrane.

-

Insert the screws through the top manifold plate, using the holes to line up the membrane.

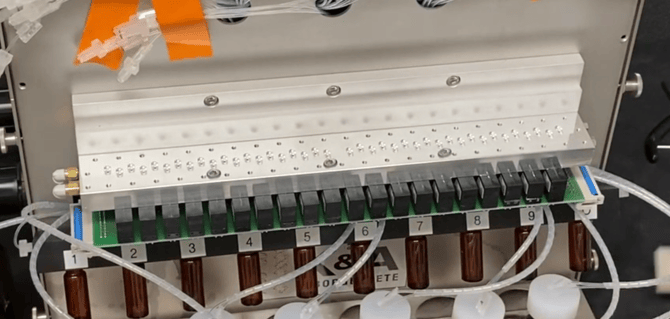

6. Reassemble Manifold Block

-

Start one screw at each end by hand using the 2.5 mm Allen wrench.

-

Lightly insert remaining screws starting from the center outward to evenly distribute torque

-

Tighten all screws by hand to finish—do not over-tighten.

🔁 Repeat this full process for any upper valve blocks or multiple membranes that need replacement.

7. Inspect and Replace Fittings

-

Inspect male luer fittings under each column. Replace if needed.

-

Use a guitar string to clear any new fittings before installing.

-

Use an 8 mm wrench to reinstall and tighten all fittings.

-

Replace damaged fittings with flangeless spares as necessary. Refer to this Video if a fitting replacement is needed.

8. Re-Pressurize and Test

-

Turn the compressor air valve back on.

-

Listen for leaks—tighten or replace fittings if needed.

-

Reinstall the sheet metal loom and column adapters.

-

On the PC, go to Control > Manual Control to verify tubing layout and placement of lines on the manifold.

-

Reconnect reagent/amidite lines and prime all channels.

-

Again inspect for liquid leaks.

Final Notes

- Label the lines for easier placement,

-

This membrane change procedure helps maintain consistent flow and synthesis quality.

-

If you're unsure at any step, contact Sierra BioSystems Support or refer to your K&A service manual.

-

Consider logging the procedure in your maintenance records, including membrane part number and date changed.