How to Install the Compressor for your K&A

This guide outlines how to install and connect the compressor, including oil filling, tubing connections, regulator installation, and pressure adjustment components.

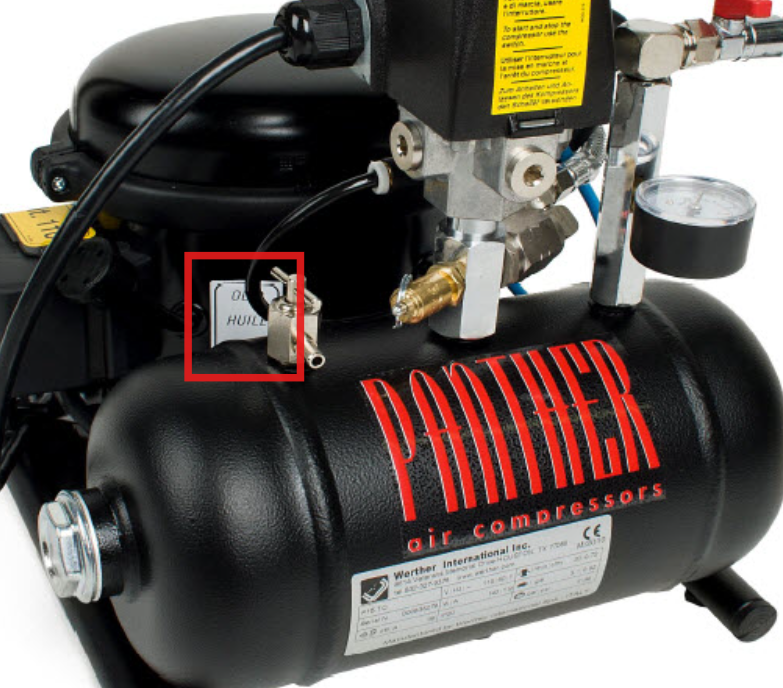

Step 1: Add Compressor Oil

-

Locate the oil fill side of the compressor:

-

European units: Typically use the left side.

-

North American units: Typically use the right side.

-

-

Use the included oil bottle:

-

Pour oil slowly into the designated oil container.

-

Watch the bubble level on the side of the compressor.

-

Stop when the bubble is halfway full. This usually takes about 70–80% of the bottle.

-

⚠️ Do not overfill. Overfilling can damage the compressor.

Step 2: Connect the Tubing

Follow the layout in the compressor schematic:

-

Attach the silicone water removal tube to the designated port.

-

Close the Vent output securely.

-

Install the muffler for noise reduction.

Step 3: Install the Regulator & Filter Assembly

-

Apply Teflon tape to the ¼” NPT-to-6mm fitting (included in your parts bin).

-

Thread the fitting into the regulator/filter:

-

Use an Allen wrench in the fitting body for better control.

-

-

Attach the regulator/filter assembly to the compressor using a crescent wrench.

-

Ensure a snug and airtight fit.

-

Step 4: Final Connections & Components

Refer to the front panel and component layout:

-

Power Switch: Turns compressor on/off

-

Manual Pressure Switch: Use to activate/deactivate compressor manually

-

Pressure Adjustment Dial: Fine-tune output pressure

-

Water Removal Switch: Releases built-up moisture from trap

-

Display Gauge: Shows active pressure

-

Water Trap & Pressure Adjustment Unit: Ensures stable output to instrument

-

Connect the 6mm output tube from the regulator to your instrument’s gas inlet

🔧 Maintenance Tip:

Drain the water trap regularly using the manual water removal switch to prevent moisture buildup and damage.